Innovation as the Catalyst for Industry Development

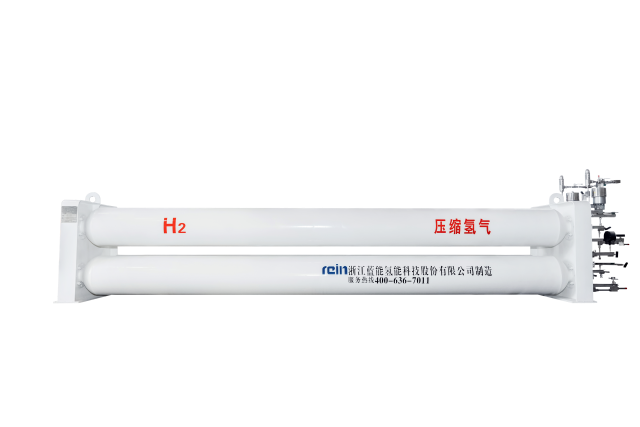

Rein is driven by a steadfast commitment to innovation, positioning itself at the forefront of technology and focusing on the development of optimal gas storage and transportation solutions to lead the industry forward.

With a strong commitment to R&D and innovation, the company has assembled a team of over 40 R&D professionals and maintained long-standing partnerships with leading Chinese universities and institutions, supported by a robust collaborative R&D platform. By leveraging key technological innovations in manufacturing, Rein delivers products that excel in performance to customers worldwide.

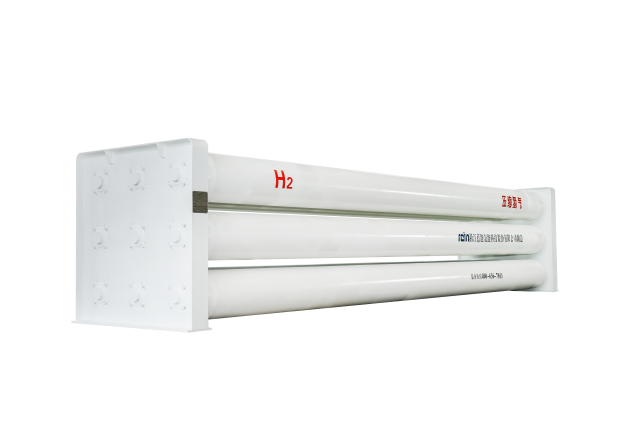

Spinning and forming

Spinning and forming

Our proprietary high-strength spinning equipment guarantees that the head formation and effective shoulder thickness of thick-walled containers adhere to high standards.

Heat treatment

Heat treatment

Our exclusive rotary double-sided spray quenching process has solved the hardenability challenge for thick-walled containers, ensuring consistent mechanical properties inside and outside.

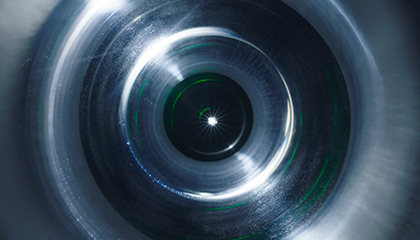

Inner wall treatment

Inner wall treatment

Rein boasts China's most advanced inner wall grinding production line and technical expertise, achieving a surface roughness of less than Ra0.2μm. We also ensure that moisture and oxygen content strictly comply with the required standards.

Sealing process

Sealing process

Our proprietary triple-sealing process guarantees exceptional sealing performance, with key technical and performance indicators meeting cutting-edge international standards.

Filament winding

Filament winding

Our industry-leading filament winding design and process enhance the strength utilization factor of fibers, ensuring exceptional performance of filament winding products such as Type II, Type III, and Type IV cylinders.

R&D Innovations

Delivering Value to Customers with Technology and Innovation

Rein spearheads global technical researches in fiber optic monitoring for temperature fluctuations, deformation, and hydrogen leakage in in-service containers. The company has overcome over ten significant technical hurdles, including hydrogen compatibility testing for high-strength steel, spin necking forming of thick-walled seamless steel pipes, heat treatment of ultra-thick seamless gas cylinders, sealing design for high-pressure hydrogen storage containers, and fatigue life fracture mechanics calculations. Rein has pioneered multiple original or leading technical pathways and solutions in China, offering customers hydrogen storage cylinders that are safer and more dependable.

Pioneering the future of clean energy,

exploring innovative hydrogen technologies

Contact us for expert storage and transportation solutions