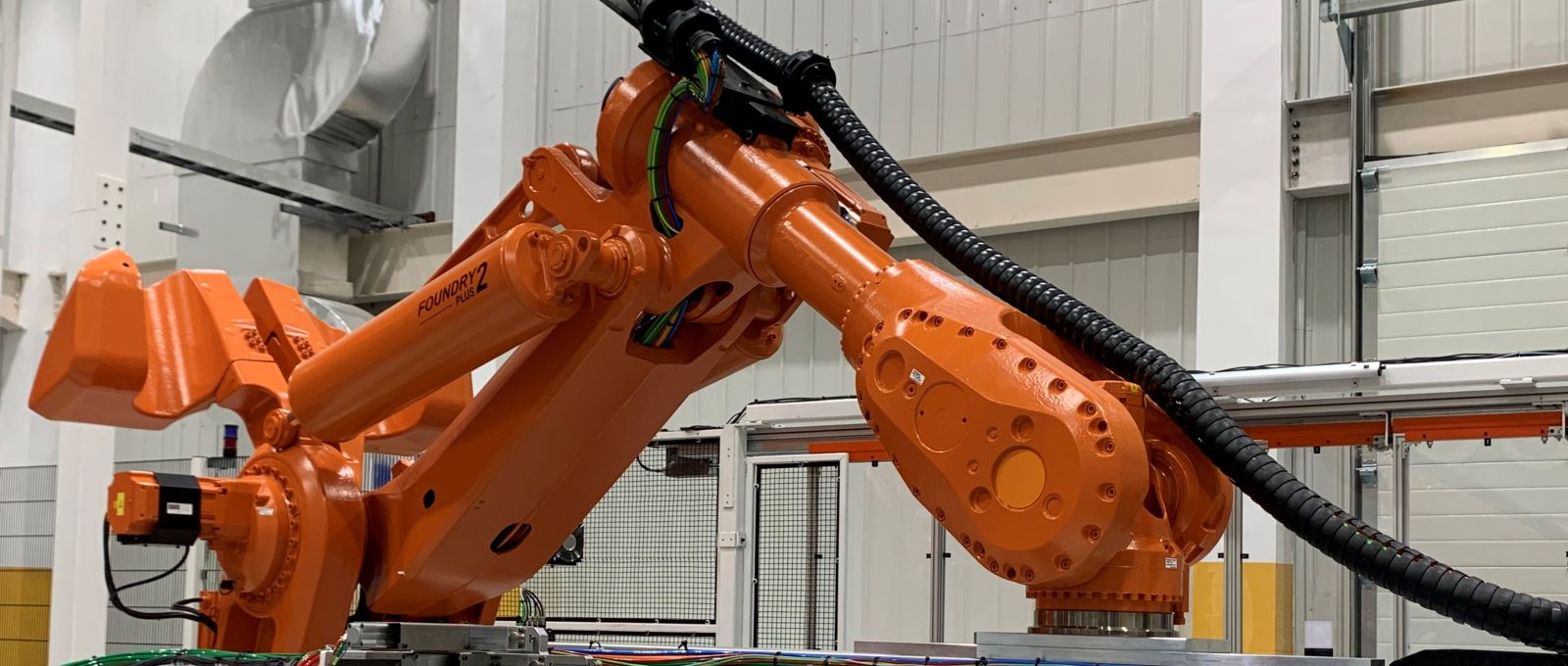

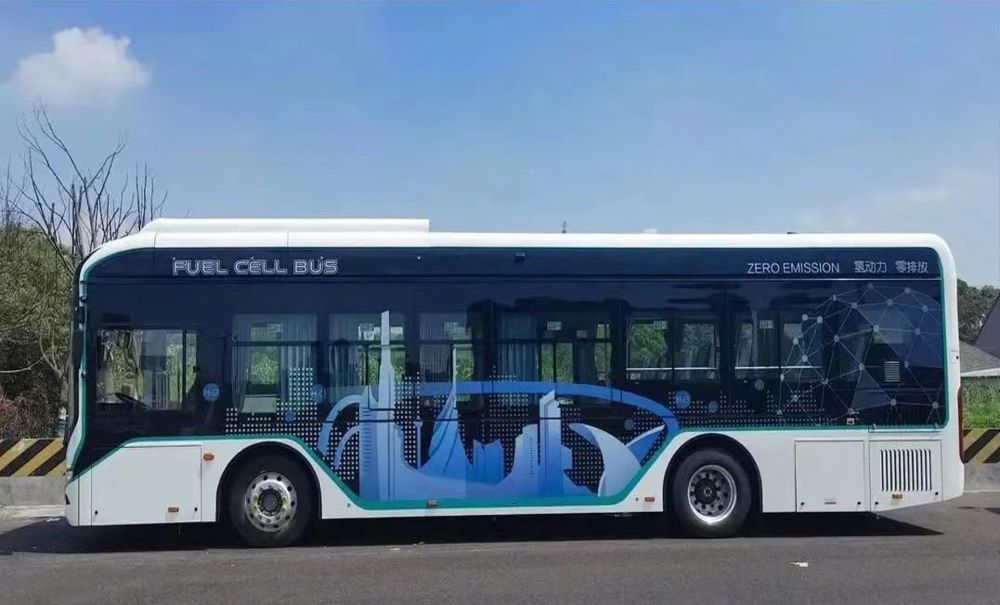

Malaysia Hydrogen-Powered Smart Tram Project

- Project location:Malaysia

- Delivery time:2024

- Project Highlight:The largest order of 70MPa Type IV hydrogen storage system in China, and the first Chinese supplier to apply high-pressure Type IV hydrogen storage system technology to rail transportation